WAREHOUSE MANAGEMENT SYSTEM

DISCOVER OUR WMS

Optimize your pick and pack process and automate your entire warehouse with Itsperfect’s fully integrated WMS. Web-based, with a super intuitive front-end, to be used on any handheld scanner. The perfect module for any fashion brand with an in-house warehouse.

FULLY INTEGRATED WMS FOR FASHION

Itsperfect is the only fashion ERP software with a fully in-house developed Warehouse Management System (WMS). And that offers a lot of advantages. For example, in the ERP, you see immediately who is picking what, you have real-time status insight, you reduce the chance of errors through the real-time sync, and it ensures the perfect cooperation between departments. Everything for smooth management of all your fashion logistics processes.

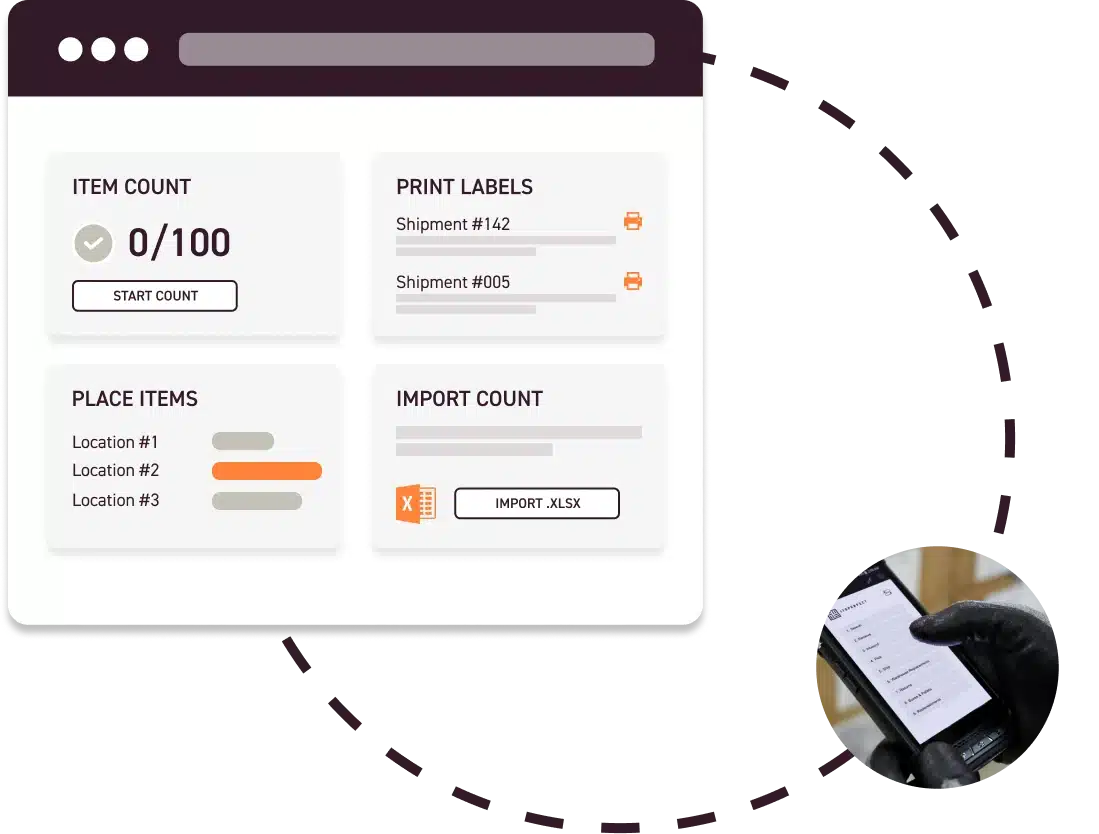

GOODS RECEIPT

Just what you need as a warehouse worker to make the inbound process as orderly as possible

CHECK ITEMS

Count items and place them in boxes or import them from an Excel document

INTERNAL BOX LABELS

Print internal box labels to temporarily label the pick during partial picking and track inventory. Upon actual delivery, replace this label with the forwarder label

AUTOMATIC PICK LOCATION

Use trollys to temporarily store goods for inbound management, let the system create efficient walking routes, and place items at pick locations automatically

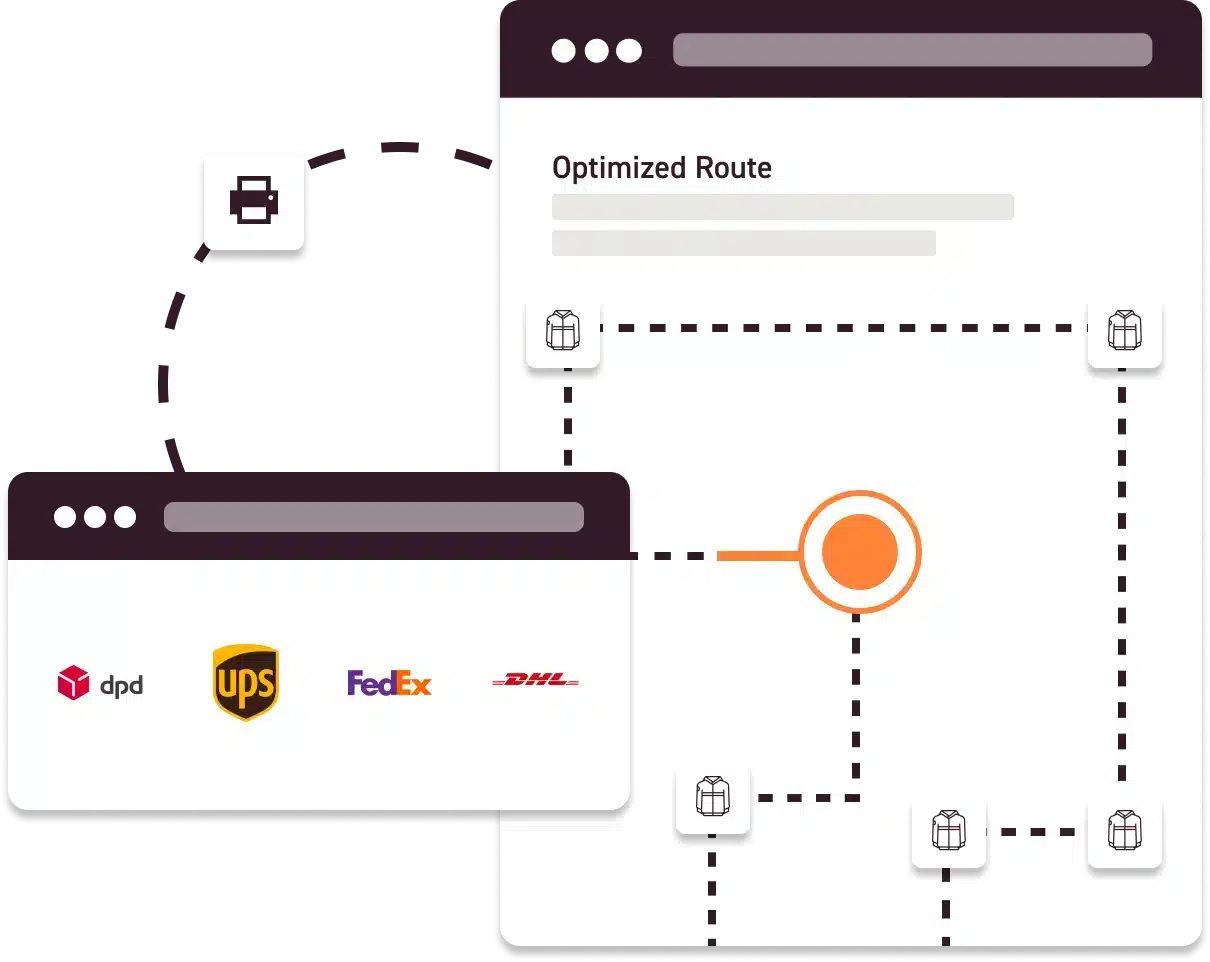

DELIVER

OPTIMIZED WALKING ROUTE

Deliver items via an optimized walking route

BOX AND PALLET MANAGEMENT

Handle boxes and pallets most efficiently, including box/pallet contents at item and SKU level

SHIPPING LABELS

Automatically generate shipping labels and open a pick for reprinting shipping labels, delivery notes, or the commercial invoice

PARTIAL PICKING

Divide large orders among multiple pickers or pick the order itself in different parts if it is spread across multiple locations

OPTIMIZED DELIVERY WITH BATCH PICKING

SINGLE BOX PICKING

Pick based on volumetric weight multiple orders in 1 batch. Collect as many orders as possible on a cart first and then walk them as efficiently as possible in 1 round

SINGLE LINE PICKING

Avoid walking endlessly through the warehouse for 1 item each time, walk an optimized round with a collection of picks

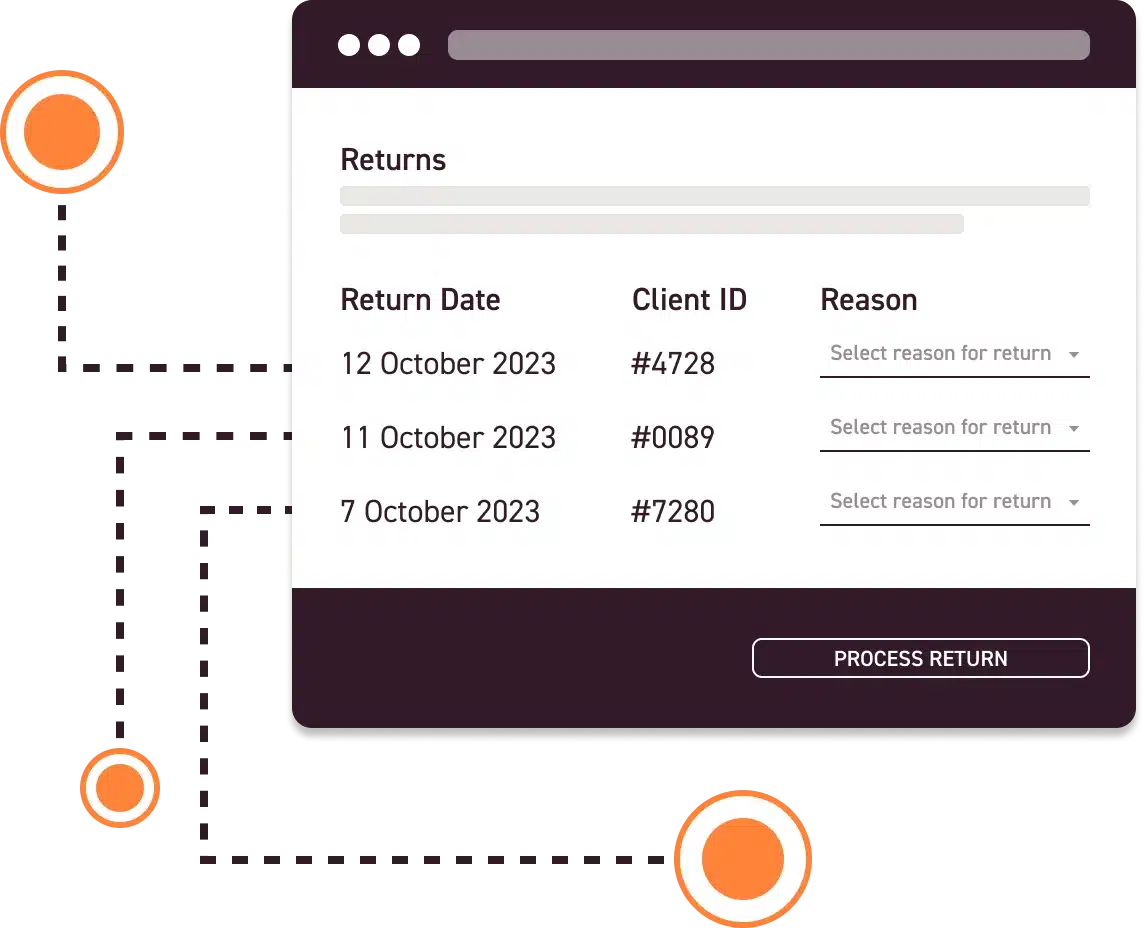

RETURNS

NEW RETURNS

Create new returns based on initial delivery

B2B RETURN RECEIVED

B2B returns are created in the ERP, these are received in the WMS where they are automatically credited

RETURN REASONS

Store return reasons with the return and gain more insight into the return process

OPTIMIZED RETURN STORAGE

Prevent warehouse workers from continuously walking. Place received items back on site according to an optimized walking route. For example, using cart management, use trollys to store goods temporarily to place them on a rack later.

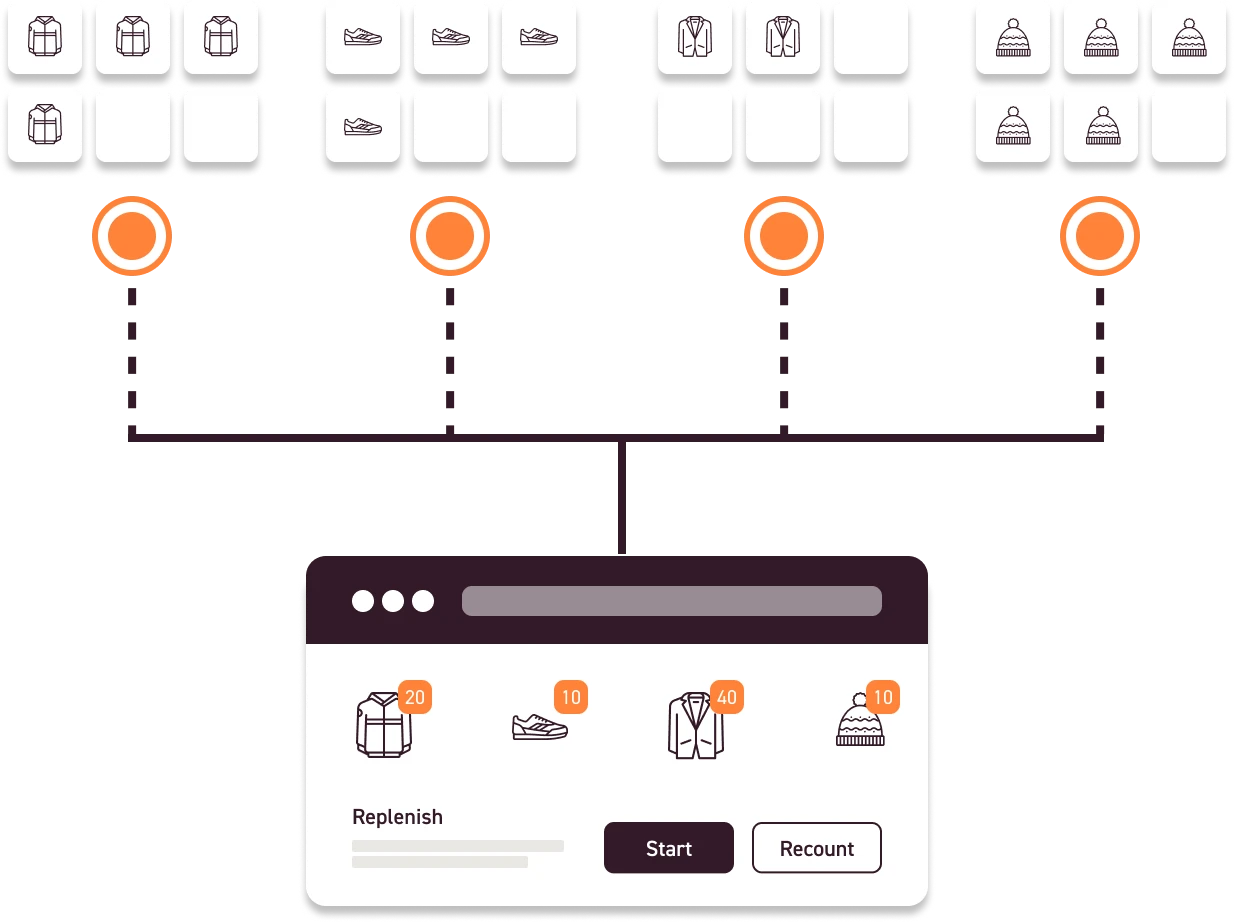

REPLENISHMENT

Replenishment, replenish the pick locations based on the bulk inventory. The software naturally takes into account all open picking orders.

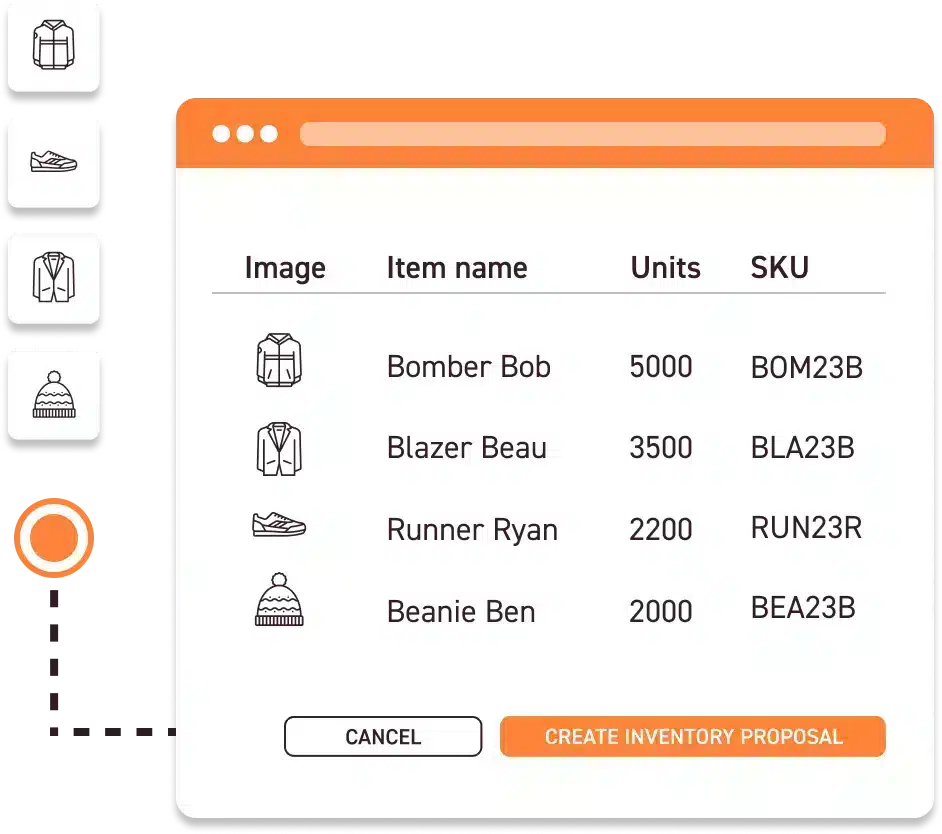

AUTOMATIC INVENTORY

Of course, it is still possible to choose your rack and count your items manually, but we are happy to help you digitize this bit. This allows you to automatically cycle count during the picking process. The system checks with the last item if it is correct that you are picking it. In addition, it is possible to create inventory proposals from the ERP. This can be based on defect reports as well as rack specifications, such as the number of pieces present. Here, the scanner indicates the location of the rack and the items to be inventoried. Pretty convenient!

OTHER USEFUL FEATURES

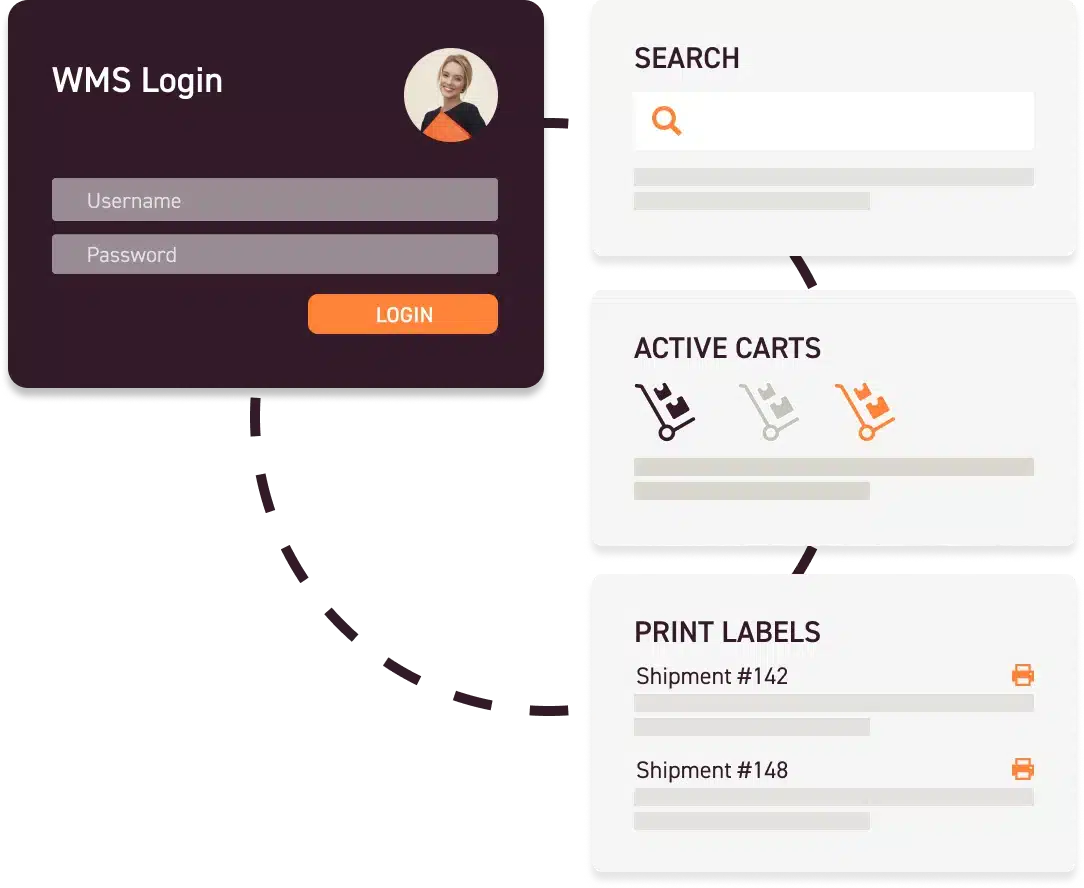

HANDY SEARCH TOOL

To quickly search for pallets, boxes, items and carts

RECEIVE GOODS VIA CARTS

And optimize the warehousing process of goods

PRINTING ON DEMAND

Create separate printers for delivery notes and labels, which can be printed "on demand" or automatically

CREATE ZONES AND WAREHOUSE FLOORS

So that the system can take into account the warehouse layout

SHORTAGE DATE STORED ON LOCATION

An additional means of control when reporting shortage, so that stock is not simply written off

CLEAR CONTROL CENTER

Check open activities and tasks in 1 view, set shortcuts, adjust settings, and change users

RFID

Easily connect the WMS with innovative RFID platforms, such as Nedap Harmony, to automate your logistics

BOX & PALLET NUMBERING

Define manual box and pallet numbering for traceability of your items in the warehouse

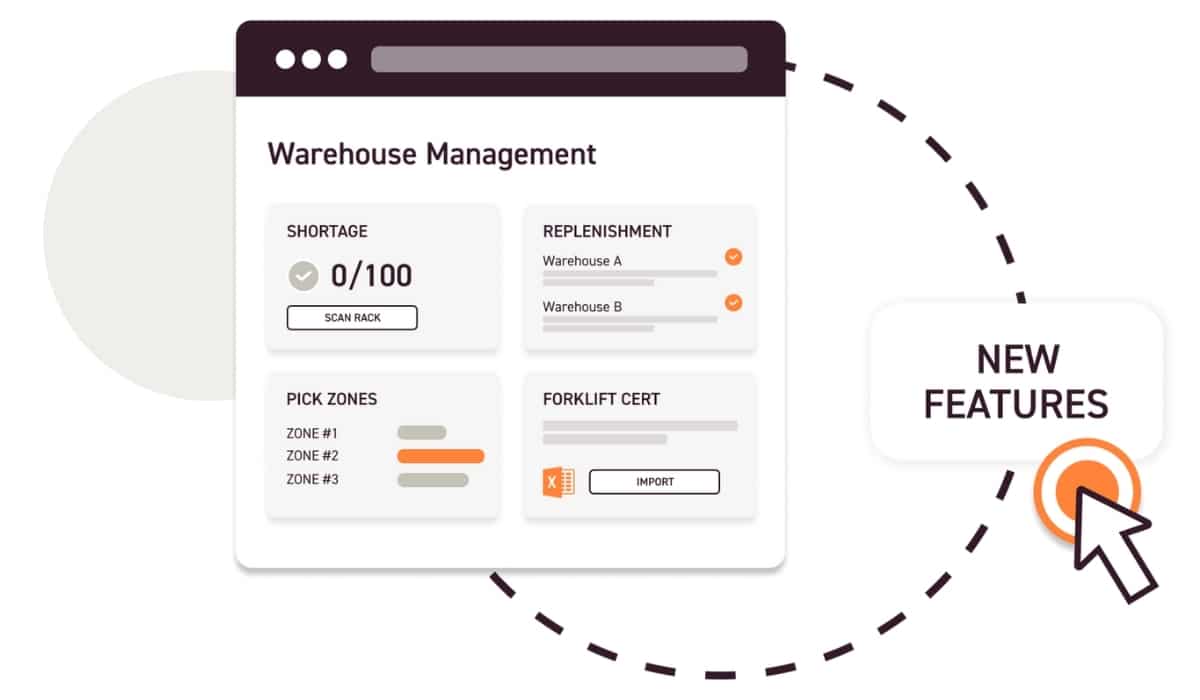

LATEST FEATURES

CONFIRM ADDITION OF NEW BOX

When you generate a new box within the WMS, the message appears: "Are you sure you want to create a new box?" This is to prevent incorrectly creating empty boxes in the WMS.

SHORTAGE: SCAN RACK FOR CONFIRMATION

When a shortage is indicated on the WMS scanner, with a quantity of more than 2 items, the message appears: "Because you want to report a shortage of more than 2 pieces, an investigation may be started." In addition, a shortage will only be accepted by the scanner after the shelf where the shortage has been detected has been scanned for confirmation.

WMS REPLENISHMENT: MULTIPLE PICKERS

A WMS replenishment proposal can be assigned to multiple pickers. They can jointly execute the same WMS replenishment order. The pickers can be assigned (automatically) in the replenishment proposal.

FORKLIFT CERTIFICATE

You can indicate for each picker whether he has a forklift certificate and for each bulk location whether it is only accessible with a forklift. Once these settings have been made, the replenishment worksheet ensures that orders for replenishment from bulk locations with forklift indications are only assigned to pickers with a forklift certificate.

PALLET RESTRICTION

When creating a pick batch template, you can choose to set Pallet restriction to Yes. This ensures that a pick from a pick batch with pallet restriction that is scanned onto a pallet after picking is checked for the pick batch ID. The scanner provides a notification when a different pick batch is scanned on a pallet.

PICK ZONES

Create pick zones at warehouse level, for example, when a warehouse consists of multiple floors. When creating pick batches, you can choose to do this for a specific pick zone, so that the picks take place on a single floor.

Want to know more about our comprehensive WMS module? Book an online demo and try it yourself!